Introducing the sustainable building material hempcrete.

As the name suggests, hempcrete or hemplime is a bio-composite utilised as a construction and insulation material. It is made of the inner woody core (‘Shiv’) of the hemp plant mixed with a lime-based binder.

Historically hemp has been utilised in construction since ancient times. For instance, a Roman bridge in France (ancient Gaul), dating from the sixth century utilised a hemp mortar.

Since the late twentieth century this material has been enjoying something of a renaissance as a sustainable building material.

Hempcrete is not structural and is very light weight. It can be formed into:

- Blocks

- Panels (caste in formwork)

- Applied as a render (approx. 50mm thick).

Green credentials:

- Renewable resource – grown as an annual crop (often in rotation with barley or rye)

- Natural resistance to insects – requiring no fertilizer, weed killer, pesticide or fungicide

- Hemp plant is versatile and can be utilised as a food supplement (rich in Omega-3 oil, amino acids, protein and fibre), outer fibres can be used for cloth (usually a blend with 45% cotton), inner core utilised for hempcrete

- If sourced locally it is low carbon

- High R value (thermal resistance) – a great insulation material that reduces energy requirements for heating / cooling

- Fire resistant

- Breathable – absorbs / desorbs water vapour (humidity)

- Recyclable

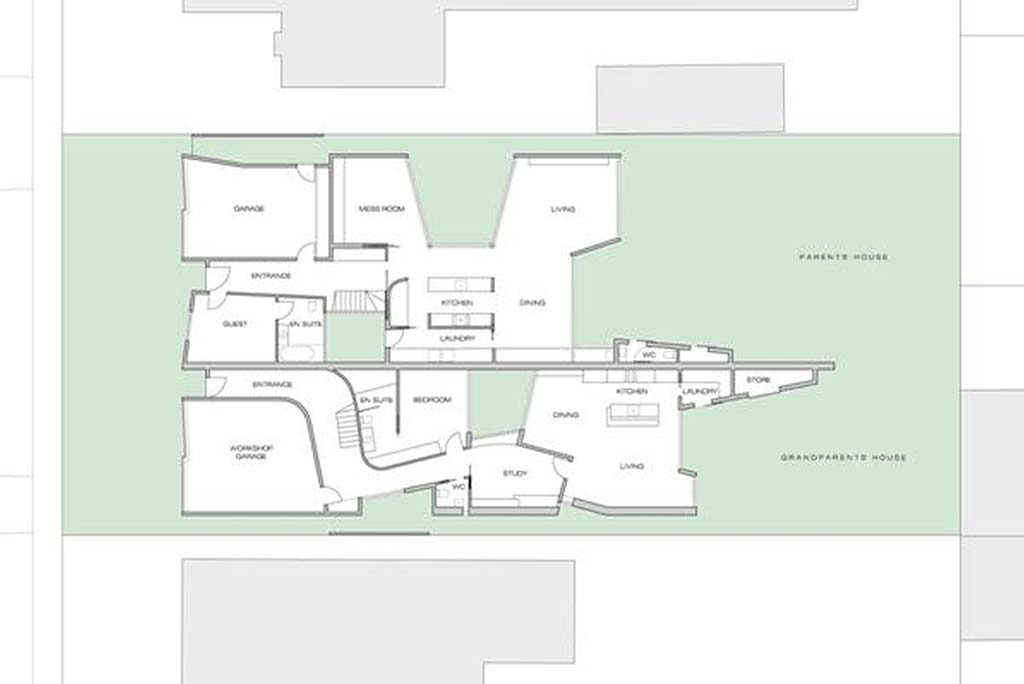

Check out Hemp House, a dual occupancy located in Melbourne VIC, designed by Steffen Welsch Architects. The 8 star, energy rated residences are credited with being the first hempcrete homes to be built in mainland Australia.

Click here to visit the Steffen Welsh Architects website and learn more about their project.

- Article: Vanessa Couzens

- Image 1: Corridor inside Hemp House designed by Steffen Welsch Architects

- Photographer: Rhiannon Slatter

- Image 2: Floor plan for Hemp House dual occupancy development, Melbourne VIC, designed by Steffen Welsch Architects (Plan source: arch20 website)